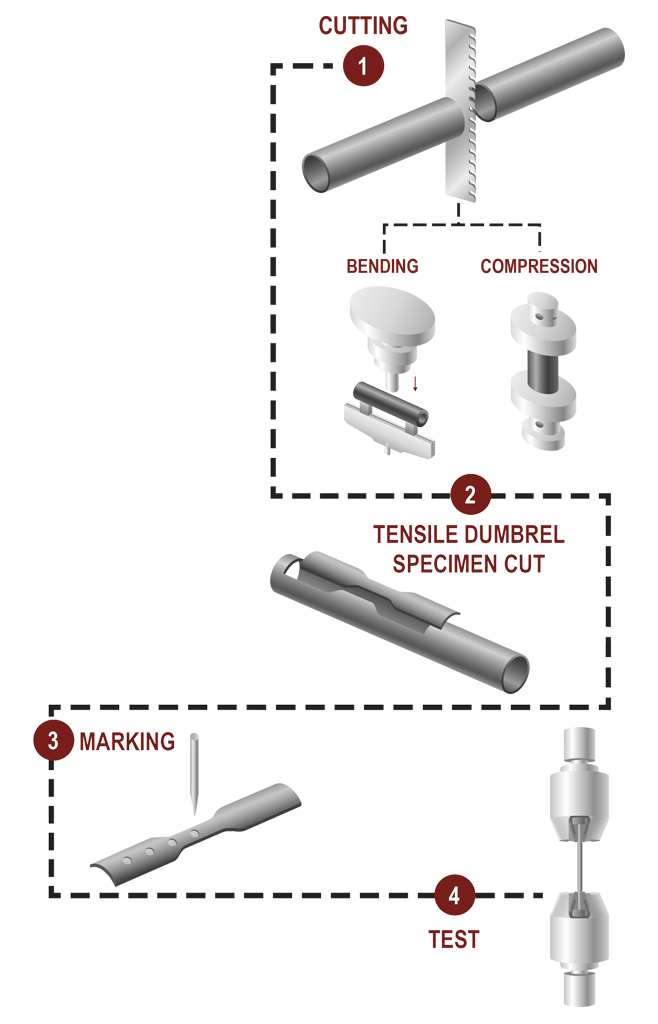

Tensile Test

Tensile testing is one of the simplest and most

widely used destructive mechanical testing

method that subjects a material sample to

uniaxial tension until failure.

A machined specimen is placed in the testing

machine and load is applied. An extensometer is

used to measure elongation.

The stress obtained at the highest applied force

is the Tensile Strength. The Yield Strength is the

stress at which a prescribed amount of plastic

deformation is produced. Elongation describes

the extent to which the specimen stretched

before fracture.

Information concerning the strength, stiffness,

and ductility of a material can be obtained from

a tensile test. Variations of the tensile testing

include : room temperature, low and high

temperature, shear tests, etc.

Many performance parameters can be measured

by tensile testing. The resulting data, a curve

of force vs extension, shows the tensile profile

of the test up to the point where the specimen

breaks. Along this tensile profile there are many

points of interest, chief among them the elastic

limit and force to break or failure point.

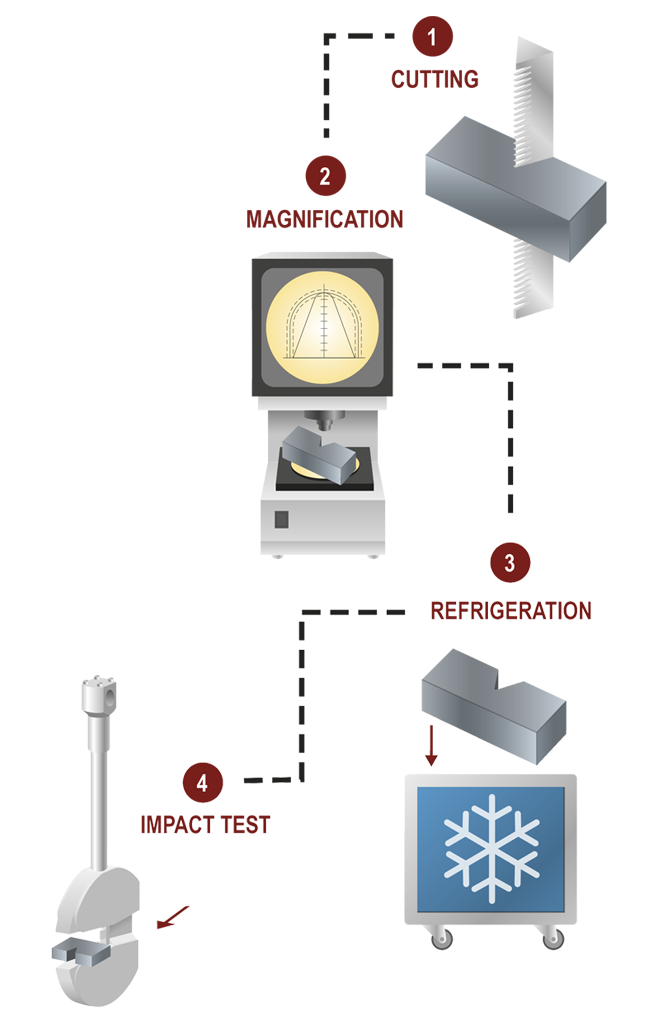

Impact Test

In material science, resilience is the ability of a

material to absorb energy when it is deformed

elastically, and release that energy upon

unloading. Proof resilience is defined as the

maximum energy that can be absorbed up to

the elastic limit, without creating a permanent

distortion. The modulus of resilience is defined

as the maximum energy that can be absorbed

per unit volume without creating a permanent

distortion.

In the laboratories the resilience is calculated

by the Charpy and Izod impact testing tests. The

apparatus consists of a pendulum of known

mass and length which is released from a

known height to impact a notched specimen.

The energy transferred to the material can be

inferred by comparing the difference in the

height of the hammer before and after the

fracture (energy absorbed by the fracture event).

The notch in the sample affects the results of the

impact test, thus it is necessary for the notch

to be of regular dimensions and geometry. The

size of the sample can also affect results, since

the dimensions determine whether or not the

material is in plane strain.

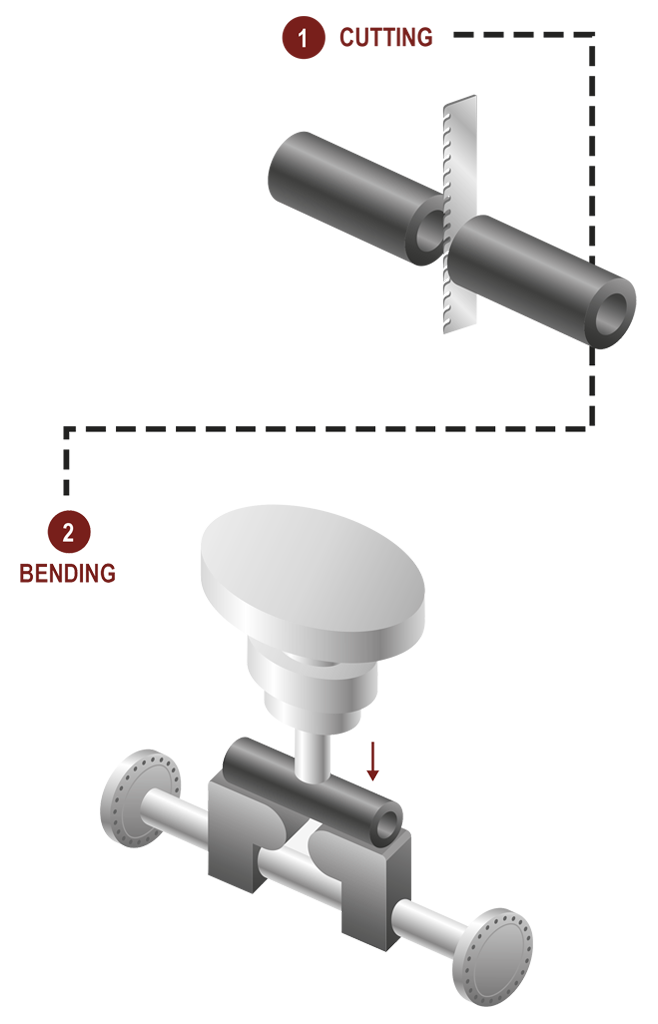

Bending Test

The bending flexural test provides modulus

of elasticity in bending values, flexural stress,

flexural strain and the flexural stress-strain

response of the material.

The upper-positioned cylinder applies the

bending force to specimen at preset angle.

Then two oppsite horizontal cylinders bend the

specimen to required angle.

The common test requires machines which allow

180° bend test with complete sets of mandrels

according to international standards.